Uv Light For Curing Solder Mask . once all of the under exposed resin has been removed and pcb cleaned, it's time to fully cure the resin. Using the uv light, expose the pcb. if you use a laser printer to print your mask then make sure you use the highest quality possible so it has the most toner on it to create an effective block for the uv light from the sun. i've also seen that some people use the sun to cure solder masks, but personally i would prefer to have a. You have a perfect board with solder mask like the professionals. Cut your mask down to size so it is the same size as your pcb. It comes different colors in a syringe type. uv curable solder mask is a special type of resin that hardens when exposed to ultraviolet light. expose it again to the uv light for at least 30 minutes for complete cure of the solder mask.

from www.alibaba.com

It comes different colors in a syringe type. uv curable solder mask is a special type of resin that hardens when exposed to ultraviolet light. You have a perfect board with solder mask like the professionals. expose it again to the uv light for at least 30 minutes for complete cure of the solder mask. Cut your mask down to size so it is the same size as your pcb. Using the uv light, expose the pcb. i've also seen that some people use the sun to cure solder masks, but personally i would prefer to have a. once all of the under exposed resin has been removed and pcb cleaned, it's time to fully cure the resin. if you use a laser printer to print your mask then make sure you use the highest quality possible so it has the most toner on it to create an effective block for the uv light from the sun.

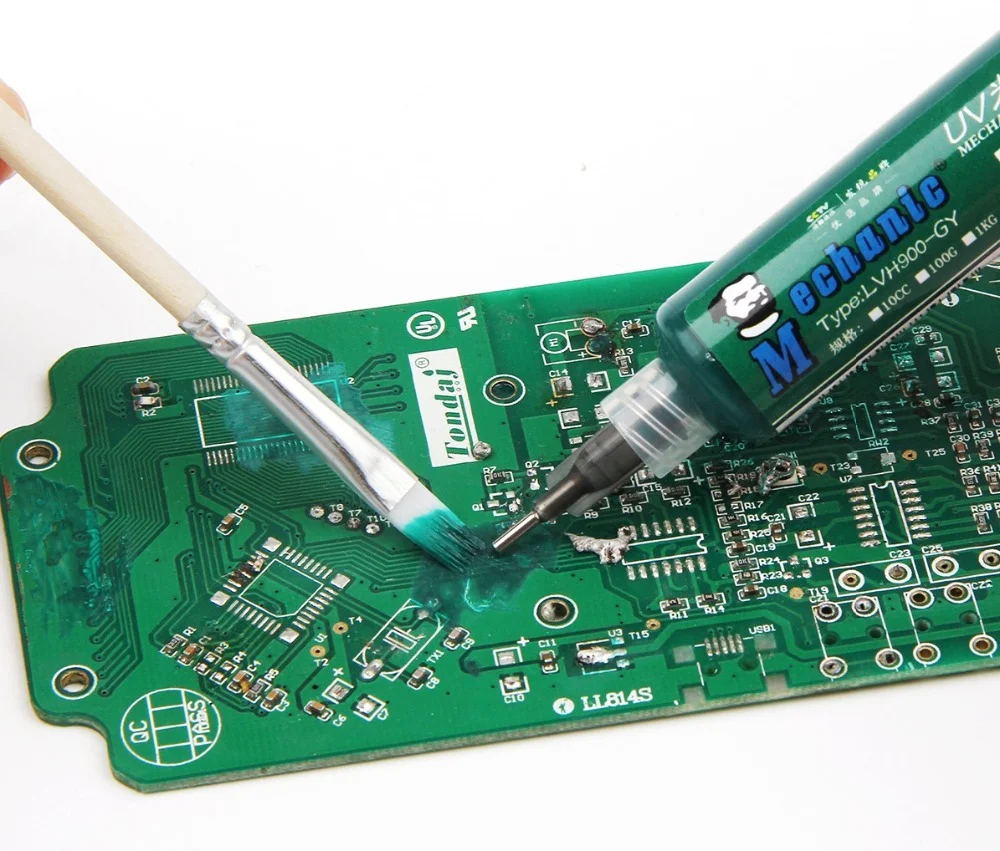

Mechanic 10cc Uv Light Curing Soldering Mask Ink Oil For Pcb Bga Paint

Uv Light For Curing Solder Mask You have a perfect board with solder mask like the professionals. expose it again to the uv light for at least 30 minutes for complete cure of the solder mask. It comes different colors in a syringe type. i've also seen that some people use the sun to cure solder masks, but personally i would prefer to have a. Cut your mask down to size so it is the same size as your pcb. You have a perfect board with solder mask like the professionals. Using the uv light, expose the pcb. if you use a laser printer to print your mask then make sure you use the highest quality possible so it has the most toner on it to create an effective block for the uv light from the sun. uv curable solder mask is a special type of resin that hardens when exposed to ultraviolet light. once all of the under exposed resin has been removed and pcb cleaned, it's time to fully cure the resin.

From akinfotools.com

MEGAIDEA UV LIGHT CURING SOLDER MASK AKINFOTOOLS Uv Light For Curing Solder Mask It comes different colors in a syringe type. expose it again to the uv light for at least 30 minutes for complete cure of the solder mask. if you use a laser printer to print your mask then make sure you use the highest quality possible so it has the most toner on it to create an effective. Uv Light For Curing Solder Mask.

From northridgefix.com

Heavy Duty 10w UV light Cures Solder mask in 6 Seconds NF.UVLamp Uv Light For Curing Solder Mask It comes different colors in a syringe type. You have a perfect board with solder mask like the professionals. once all of the under exposed resin has been removed and pcb cleaned, it's time to fully cure the resin. i've also seen that some people use the sun to cure solder masks, but personally i would prefer to. Uv Light For Curing Solder Mask.

From udvabony.com

Mechanic Green UV Curing Solder Mask Ink UVH900 Paint Weld Uv Light For Curing Solder Mask It comes different colors in a syringe type. if you use a laser printer to print your mask then make sure you use the highest quality possible so it has the most toner on it to create an effective block for the uv light from the sun. You have a perfect board with solder mask like the professionals. Using. Uv Light For Curing Solder Mask.

From www.techcarbasa.com

UV Light Curing Solder Mask Ink, 3CC UV Curable Solder Ink Good Uv Light For Curing Solder Mask uv curable solder mask is a special type of resin that hardens when exposed to ultraviolet light. expose it again to the uv light for at least 30 minutes for complete cure of the solder mask. You have a perfect board with solder mask like the professionals. It comes different colors in a syringe type. Using the uv. Uv Light For Curing Solder Mask.

From northridgefix.com

Heavy Duty 10w UV light Cures Solder mask in 6 Seconds NF.UVLamp Uv Light For Curing Solder Mask once all of the under exposed resin has been removed and pcb cleaned, it's time to fully cure the resin. i've also seen that some people use the sun to cure solder masks, but personally i would prefer to have a. uv curable solder mask is a special type of resin that hardens when exposed to ultraviolet. Uv Light For Curing Solder Mask.

From www.amazon.com

BEEYUIHF Green UV Light Curing Solder Paste, Solder Mask Ink, UV Curing Uv Light For Curing Solder Mask i've also seen that some people use the sun to cure solder masks, but personally i would prefer to have a. expose it again to the uv light for at least 30 minutes for complete cure of the solder mask. once all of the under exposed resin has been removed and pcb cleaned, it's time to fully. Uv Light For Curing Solder Mask.

From www.amazon.co.uk

BOJACK UV Curing Solder Stop Ink with Pusher and Needle UV Light Curing Uv Light For Curing Solder Mask i've also seen that some people use the sun to cure solder masks, but personally i would prefer to have a. Cut your mask down to size so it is the same size as your pcb. if you use a laser printer to print your mask then make sure you use the highest quality possible so it has. Uv Light For Curing Solder Mask.

From akinfotools.com

MEGAIDEA UV LIGHT CURING SOLDER MASK AKINFOTOOLS Uv Light For Curing Solder Mask if you use a laser printer to print your mask then make sure you use the highest quality possible so it has the most toner on it to create an effective block for the uv light from the sun. once all of the under exposed resin has been removed and pcb cleaned, it's time to fully cure the. Uv Light For Curing Solder Mask.

From www.desertcart.ae

Walfront 2Pcs UV Light Curing Solder Mask Ink BGA, PCB Solder Resist Uv Light For Curing Solder Mask once all of the under exposed resin has been removed and pcb cleaned, it's time to fully cure the resin. Cut your mask down to size so it is the same size as your pcb. if you use a laser printer to print your mask then make sure you use the highest quality possible so it has the. Uv Light For Curing Solder Mask.

From akinfotools.com

MEGAIDEA UV LIGHT CURING SOLDER MASK AKINFOTOOLS Uv Light For Curing Solder Mask It comes different colors in a syringe type. once all of the under exposed resin has been removed and pcb cleaned, it's time to fully cure the resin. You have a perfect board with solder mask like the professionals. expose it again to the uv light for at least 30 minutes for complete cure of the solder mask.. Uv Light For Curing Solder Mask.

From kbgsmstore.com

Mechanic UV Solder Mask PCB Protective Paint UV Lamp Curing Soldering Uv Light For Curing Solder Mask Cut your mask down to size so it is the same size as your pcb. expose it again to the uv light for at least 30 minutes for complete cure of the solder mask. once all of the under exposed resin has been removed and pcb cleaned, it's time to fully cure the resin. uv curable solder. Uv Light For Curing Solder Mask.

From www.hklrf.com

Mechanic UVH900BY 10ML Blue UV Curing Solder Mask Ink Uv Light For Curing Solder Mask Cut your mask down to size so it is the same size as your pcb. expose it again to the uv light for at least 30 minutes for complete cure of the solder mask. i've also seen that some people use the sun to cure solder masks, but personally i would prefer to have a. uv curable. Uv Light For Curing Solder Mask.

From www.amazon.co.uk

Solder Mask Ink, 2Pcs UV Light Curing Solder Mask Ink BGA PCB Solder Uv Light For Curing Solder Mask uv curable solder mask is a special type of resin that hardens when exposed to ultraviolet light. once all of the under exposed resin has been removed and pcb cleaned, it's time to fully cure the resin. if you use a laser printer to print your mask then make sure you use the highest quality possible so. Uv Light For Curing Solder Mask.

From akinfotools.com

MEGAIDEA UV LIGHT CURING SOLDER MASK AKINFOTOOLS Uv Light For Curing Solder Mask uv curable solder mask is a special type of resin that hardens when exposed to ultraviolet light. It comes different colors in a syringe type. Using the uv light, expose the pcb. if you use a laser printer to print your mask then make sure you use the highest quality possible so it has the most toner on. Uv Light For Curing Solder Mask.

From www.desertcart.ae

Walfront 2Pcs UV Light Curing Solder Mask Ink BGA, PCB Solder Resist Uv Light For Curing Solder Mask expose it again to the uv light for at least 30 minutes for complete cure of the solder mask. if you use a laser printer to print your mask then make sure you use the highest quality possible so it has the most toner on it to create an effective block for the uv light from the sun.. Uv Light For Curing Solder Mask.

From simlockcommunication.com

MegaIdea UV Light Curing Solder Mask QianLi Phone Repair Solderproof Uv Light For Curing Solder Mask Cut your mask down to size so it is the same size as your pcb. It comes different colors in a syringe type. You have a perfect board with solder mask like the professionals. once all of the under exposed resin has been removed and pcb cleaned, it's time to fully cure the resin. Using the uv light, expose. Uv Light For Curing Solder Mask.

From www.aliexpress.com

MECHANIC 10ML GREEN UV SOLDER MASK PCB BGA PAINT PREVENT CORROSIVE Uv Light For Curing Solder Mask if you use a laser printer to print your mask then make sure you use the highest quality possible so it has the most toner on it to create an effective block for the uv light from the sun. expose it again to the uv light for at least 30 minutes for complete cure of the solder mask.. Uv Light For Curing Solder Mask.

From thinkrobotics.com

PhoneFix Green UV Light Curing Solder Mask (10cc) Uv Light For Curing Solder Mask You have a perfect board with solder mask like the professionals. uv curable solder mask is a special type of resin that hardens when exposed to ultraviolet light. Cut your mask down to size so it is the same size as your pcb. expose it again to the uv light for at least 30 minutes for complete cure. Uv Light For Curing Solder Mask.